abstract for rockwell hardness test|hardness tester lab report pdf : importers TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . Programação - Programação - Rede Globo

{plog:ftitle_list}

10 de fev. de 2024 · Opt in Betway Free Bet Club: Countdown To Cheltenham Deposit a minimum of £25 and place your first bets on trebles, accumulators or Bet Builder bets Receive your two £5 Free Bets and 25 Free Spins.

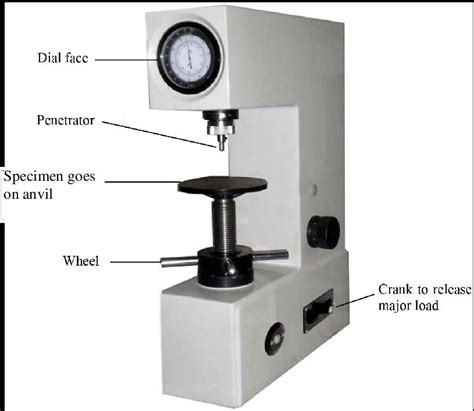

The Rockwell Hardness Test Method, as defined in ASTM E-18 is the most used hardness test. It is easy to perform, and more accurate than other types of hardness tests. In our lab, we used Rockwell method to measure the .Abstract: The Rockwell hardness test is a widely used method for evaluating the hardness of materials, particularly metals. This research paper explores the principles, applications, and . Abstract. The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you .

Macro-Hardness (Rockwell and Brinell) testing is the most commonly applied materials test in industry due to several factors: 1) Macro-Hardness Testing is simple to perform and does not . Abstract. Characteristics of the empirically developed Rockwell hardness test make it difficult to determine measurement uncertainty using methods based on mathematical models.Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .ABSTRACT alloys. Quality control of metals is a significant process in any industry. To improve the quality of metals, Brinell and Rockwell methods are used as one of the most effective. The .

Abstract Rockwell hardness (HR) is a valuable and widely used indentation hardness test for evaluating mechanical properties of metallic materials. Abstract Rockwell hardness test blocks, whether standardized at the primary national laboratory level or by secondary commercial laboratories, have been certified historically by determining an average hardness value for the test surface of the block. However, because of the hardness non-uniformity of test blocks, measurement values will be .The Rockwell hardness (HR) is then determined from the residual indentation depth, along with a few other factors (see below). In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to . Abstract. There exist various types of experimental measurement of hardness, yet a unified understanding of various hardness measurements lacks. Here, by testing the hardness of a wide range of materials, we show that Rockwell and Brinell hardness tests, the two most used hardness measurements, are closely related. The experimental .

starrett 3810a digital portable hardness tester

Abstract. The standard superficial Rockwell 15Y hardness test has been adapted for use on concrete. Hardness measurements were made on the mortar regions between the coarse aggregate pieces. A correlation between this hardness and the concrete's compressive strength was developed. For 7.5- by 15-cm (3- by 6-in.) cylinders, it is Rockwell 15Y .Abstract The mechanical properties of materials are ascertained by performing carefully designed laboratory experiments that replicate, as nearly as practical, the service conditions. . testing while Rockwell hardness is determined by the depth of the indentation made by a constant applied load. For thin test samples or samples for which the . Rockwell hardness testing machine, Journal of Testing and Evaluation, 276/ 27, 1978. . How to test . [Show full abstract] the applicability of QCD at fixed order to the heavy quark production .

[Show full abstract] standard machines and a standardized testing cycle, a worldwide unified Rockwell hardness scale could be established with metrological traceability, stability and .profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds,The ASTM standard Superficial Rockwell hardness test using a 1/2 inch ball indenter and a 15 kgf Major Loar (15Y test) were adapted to perform nondestructive hardness tests on portland cement mortars and concrete. Correlations between the compressive strength of both materials and their hardnesses were found. The correlation for normal concrete and 3 x 6 inches .

Rockwell hardness (HR) is a valuable and widely used indentation hardness test for evaluating mechanical properites of metallic materials. . Abstract Rockwell hardness (HR) is a valuable and widely used indentation hardness test for evaluating mechanical properites of metallic materials. For the Rockwell scales that use a ball indenter .

Rockwell Hardness C Test was performed on a sample of steel provided and the experimental readings are recorded with inclusion of theory, procedure, pictures of the samples after testing is done.Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a . Rockwell hardness test is the most widely employed. . [Show full abstract] obtained, with the invitation to other researchers to test velocity effect with different apparatus, .The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens .

rockwell hardness testing procedure pdf

rockwell hardness testing guide pdf

Abstract Indentation hardness tests such as Brinell, Rockwell, Vickers, Knoop, and instrumented indentation are frequently used methods for determining hardness. The basic concept utilized in all o.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . The FE analysis of Rockwell hardness test confirmed that the proposed hardness-strength-hardening law relationship based on Voce type hardening rule was sufficiently accurate in predicting the .

Abstract ISO 6508-2:2015 specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508‑1:2015, together with a method for verifying Rockwell hardness indenters. . Rockwell hardness test Calibration of reference blocks BS EN 843-4:2005: Advanced . HRB tests are conducted for materials with low range hardness, such as aluminum, brass, and soft steels, whereas HRC tests are used for materials with high range hardness, such as harder steels. Smaller weights (15 to 45 kg) are used for the Rockwell superficial hardness test such as the HR15W, which uses a 1/8 in. steel ball with a 15 kg .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. . Abstract. The Rockwell hardness (HR) test is a valuable and widely used indentation hardness test for evaluating mechanical properties of metallic materials. For the Rockwell scales that use a ball indenter, either a steel or tungsten carbide (WC) ball indenter is permitted to be used in the current standards of ASTM International and the International .

1. To perform a calibration of a Rockwell hardness tester using a standard test block; and . 2. To measure the Rockwell hardness of a steel reinforcing bar, a widely used construction material. (b) Learning Goals: 1. To be able to perform Rockwell hardness testing, a prominent techniqueThe Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters . Abstract. ISO 6508-2:2015 specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508‑1:2015, together with a method for .

starrett 3811 hardness tester manual

22 Aug 18, 2022. 2020/2021. Manchester City. 21 Sep 25, 2021. Cole Palmer (born 6 May 2002) is a British footballer who plays as a right winger for British club Manchester City. .

abstract for rockwell hardness test|hardness tester lab report pdf